Understanding IPC Standards for PCB Manufacturing A Comprehensive Guide

The electronic devices that power our daily lives—from smartphones to medical equipment—are intricately built, relying on the precise construction of their core component: printed circuit boards (PCBs). These PCBs, often regarded as the backbone of electronics, undergo a complex manufacturing process governed by industry standards set forth by the Association Connecting Electronics Industries (IPC).

Defining IPC Standards

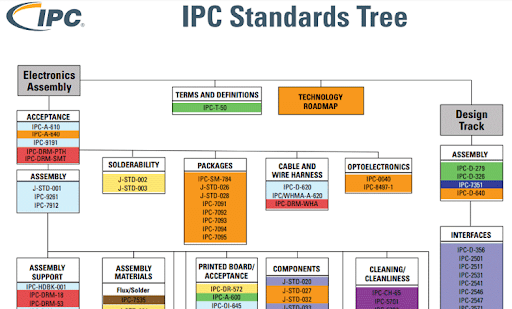

IPC standards serve as the guiding principles and benchmarks that dictate every step of the PCB manufacturing journey—from design to assembly, inspection, testing, and documentation. These standards are meticulously developed through collaboration among industry experts, ensuring adherence to specific criteria aimed at achieving optimal quality, reliability, and performance in electronic products.

IPC Class Meaning

One critical aspect of IPC standards is the classification of PCBs into different classes, denoted as IPC Class 1, Class 2, and Class 3. Each class defines the level of reliability, performance, and environmental resilience expected from the PCB. IPC Class meaning is crucial, as it guides manufacturers in understanding the precise quality requirements and design specifications necessary for different applications.

IPC and Its Role in the Electronics Industry

Initially known as the Institute for Printed Circuits, IPC was founded in 1957 by six PCB manufacturers. Over time, it evolved to become the Association Connecting Electronics Industries, representing over 4,000 member companies across diverse sectors, including aerospace, automotive, medical equipment, telecommunications, and more.

IPC’s primary objective is to establish and update standards that encompass various facets of PCB design, production, and assembly. These standards act as a common language, fostering seamless communication across the electronics industry.

Evolution and Key Milestones

IPC standards have undergone significant evolution since their inception. Key milestones, such as the publication of IPC’s first book, “How to Design and Specify Printed Circuits,” in 1958, marked the beginning of a journey towards standardization in the electronics sector.

The introduction of essential standards like IPC-A-600 for the acceptability of printed boards and IPC-A-610 for the acceptability of electronic assemblies further solidified IPC’s role in ensuring quality control and reliability.

IPC Standards in Detail

IPC-2220 Series for PCB Design: This series encompasses various standards outlining design requirements for rigid, flex, and high-density interconnect boards. IPC-2221, in particular, defines general PCB design principles, guiding designers through assembly procedures, component mounting, and more.

IPC-A-600 and IPC-A-610: These standards set criteria for the acceptability of both printed boards and electronic assemblies, providing visual inspection guidelines. IPC-A-610 serves as one of the most widely used standards, ensuring quality control during the assembly process.

IPC-JSTD-001: Focusing on soldered interconnections, this standard outlines materials, methods, and criteria for creating high-quality soldered joints. It emphasizes process control and is essential for various electronic product types.

IPC-7711/IPC-7721: These standards detail guidelines for reworking and repairing electronic assemblies, ensuring minimal impact on quality and reliability during repair processes.

Benefits of Adhering to IPC Standards

Compliance with IPC standards offer a multitude of advantages for manufacturers and designers:

Enhanced Quality Control: IPC standards ensure consistent quality, reducing defects and enhancing product reliability.

Improved Communication: These standards create a universal language, fostering seamless communication between manufacturers, suppliers, and customers.

Market Competitiveness: Adhering to industry standards enhances market competitiveness by assuring customers of superior product quality.

Reduced Time to Market: Standardized processes streamline production, reducing delays and accelerating time-to-market for electronic products.

Conclusion

In the world of electronics, IPC standards serve as the cornerstone of quality and reliability in PCB manufacturing. These meticulously crafted guidelines not only ensure adherence to industry best practices but also drive innovation and advancement, enabling the creation of cutting-edge electronic devices that power our modern world.