Hire Gear Hob Manufacturers That Support Your Machinery

Industrial functioning should be seamless, having all necessary equipment in good working condition. One product that aids in this aspect is a gear that takes in suitable manufacturing processes at the industries. The methods could vary, and as technology is evolving, many techniques are being introduced.

A good technique that most industries are identifying is gear hobbing. The presence of gear hob manufacturers is more because this method is seeing a drastic demand. They meet their client needs greatly, and every industry owner should deep dive into this gear machining method to pave the way for industrial growth with the best gear quality.

A versatile product for industries

Gears are inevitable to make any industrial machinery work properly. Its role is high, and industry owners focus more on employing the right gear model to sow seeds for the betterment of the business.The techniques to manufacture gears are casting, extrusion, blanking, forging, gear milling and more.

It is a primary product in transmitting the power and its rotational speed can be set based on the industrial requirements. Apart from regulating the speed of rotation and torque, they are capable of changing the direction. There are more factors to know about gears, and once an industry becomes aware of the gear hobbing technique, it benefits in manufacturing gears.

Gear hobbing – Quick overview and its advantages

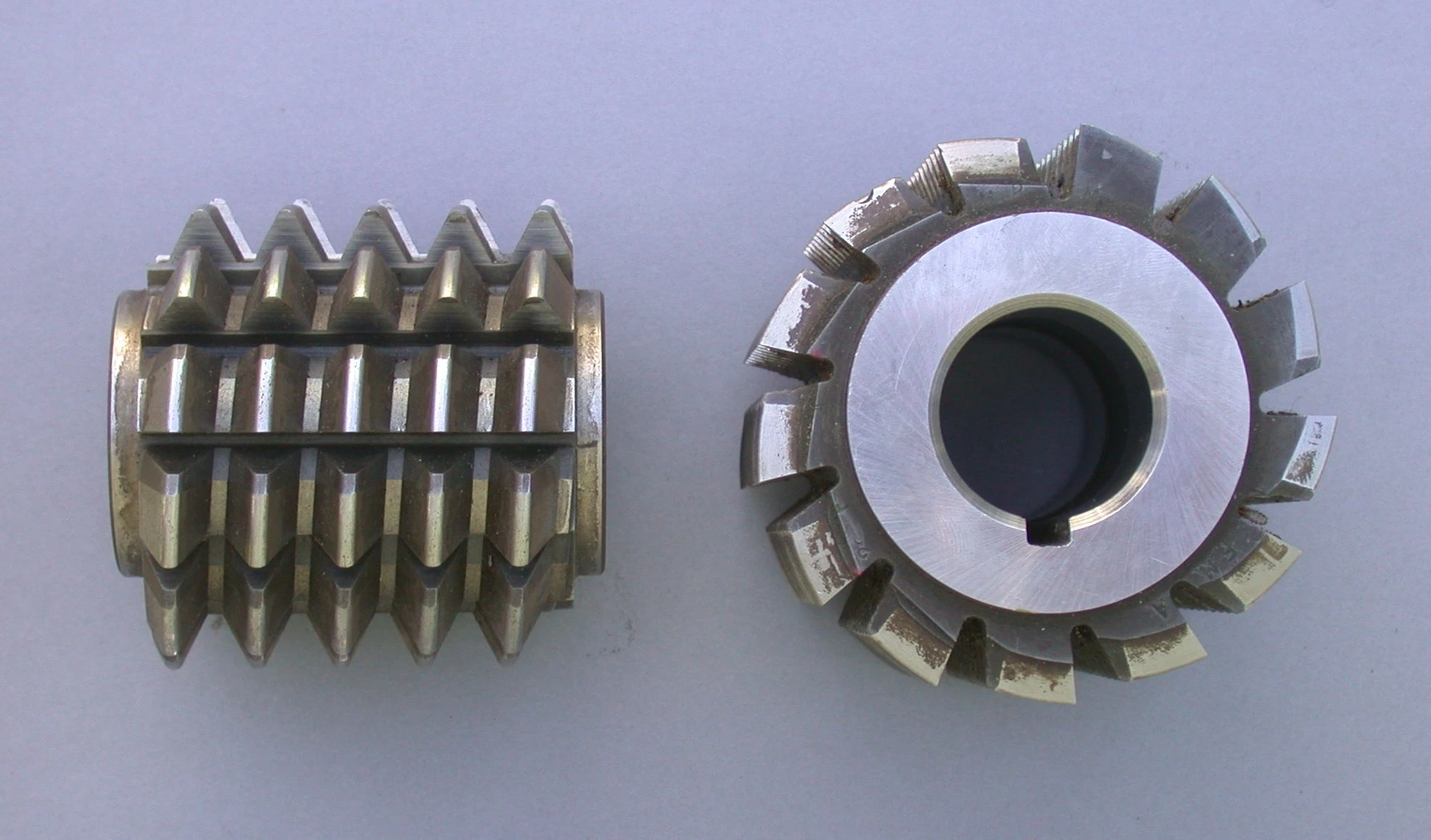

The seamless power transmission is enabled by gears with a tooth structure on its perimeter that connects with the other gears. Gear shaping and cutting techniques aid in creating these teeth effectively, and one of those techniques is gear hobbing. The hob cutters are circular and have teeth all around to enable the manufacturing of helical and spur gears.

An affordable technique that industries can choose is gear hobbing, and the gear hob cutters suppliers deliver the productin the USA countrythat requires the best quality cutters. A gist of the reasons for opting gear hobbing technique will lead to a wise decision of the technique to manufacture gears.

- Precise outcomes are the best factor and can be considered the top element to bolster the choice of gear-cutting method. Gear hobbing owns it and serves the best for industries that believe in this technique.

- An efficient operation is another key point to discuss. When you deploy a gear hob cutter, you ensure operational efficiency, and that allows you to complete the orders on time. If any client places bulk orders of different gears, using gear hob cutters to perform gear hobbing is the best. Your industry growth is unstoppable when choosing this gear machining process.

- Every product should have a standard quality that can be ensured with the gear hobbing technique. Its accuracy is exceptional, and industries can ensure their machinery is in the best condition with the manufactured gears from hob cutters. Without much operational effort, achieving good gear quality would be the outcome.

Research more on the gear hob manufacturers to go with the right choice by knowing their background and give the best for your industry to operate well.